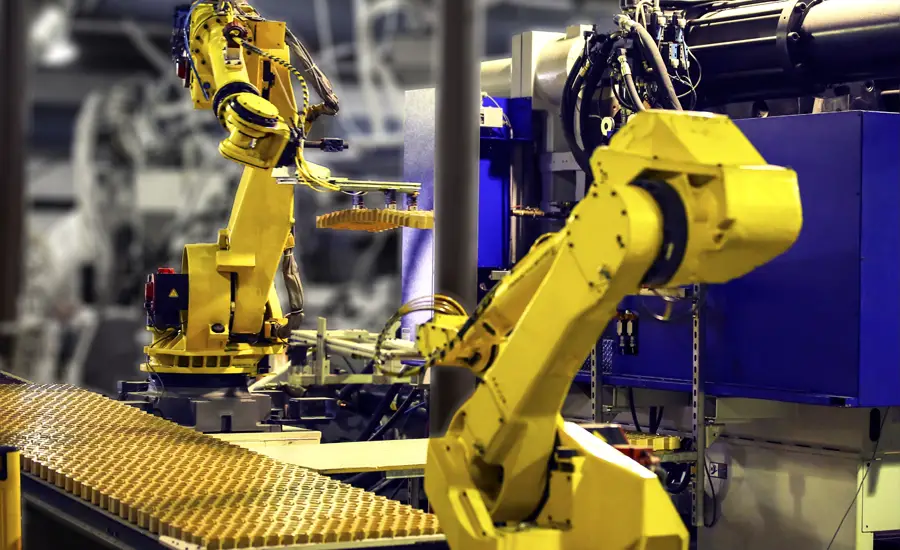

Fanuc Robots

In today’s fast-paced manufacturing world, efficiency is key. That’s why more and more companies are turning to Fanuc robots for their automation needs. Fanuc robots are known for their reliability, precision, and speed, making them an ideal choice for any production line. However, understanding how to master the efficiency of these robots can be a challenge. In this comprehensive guide, we’ll take a deep dive into the world of Fanuc robots and explore how to maximize their potential. From programming and maintenance to safety and troubleshooting, we’ll cover everything you need to know to get the most out of your Fanuc robots. So, whether you’re a seasoned robotic expert or just getting started, this guide will help you take your efficiency to the next level.

Introduction to Fanuc Robotics and their impact on industrial automation

Fanuc Robots have revolutionized industrial automation with their cutting-edge technology and precision engineering. These robots, developed by Fanuc Corporation, a global leader in robotics and automation systems, have made significant impacts across various industries, from automotive manufacturing to electronics assembly.

With their advanced capabilities and versatility, Fanuc Robots have helped companies streamline their production processes, increase efficiency, and improve overall productivity. These robots are designed to perform a wide range of tasks with speed, accuracy, and consistency, making them invaluable assets for any manufacturing operation.

In this comprehensive guide, we will delve into the world of Fanuc Robots, exploring their key features, applications, and the benefits they bring to the industrial automation sector. Whether you are a seasoned industry professional or just getting started with automation, mastering efficiency with Fanuc Robots is essential for staying competitive in today’s fast-paced manufacturing environment.

Understanding the key features and capabilities of Fanuc RoboticsFanuc Robots are renowned for their cutting-edge technology and advanced capabilities, making them a popular choice for industrial automation. These robots are equipped with a wide range of features that enhance efficiency and productivity in manufacturing processes. Understanding the key features and capabilities of Fanuc Robots is essential for maximizing their potential in your operations.

One of the standout features of Fanuc Robots is their precision and accuracy. These robots are known for their high repeatability and precision, allowing them to perform intricate tasks with utmost accuracy. Whether it’s welding, material handling, painting, or assembly, Fanuc Robots excel in delivering consistent and precise results, ensuring quality and reliability in production processes.

Furthermore, Fanuc Robots are designed to be versatile and adaptable to various manufacturing needs. With a wide range of payload capacities, reach options, and configurations available, these robots can be customized to suit specific requirements and applications. Whether you need a compact robot for confined spaces or a heavy-duty robot for lifting heavy loads, Fanuc Robots offer a diverse range of options to meet your needs.

In addition to their technical capabilities, Fanuc Robots are also known for their user-friendly interface and intuitive programming features. With easy-to-use programming software and intuitive teach pendant controls, operators can quickly set up and program these robots for different tasks. This user-friendly interface not only enhances efficiency but also reduces training time and costs, making Fanuc Robots accessible to operators of all skill levels.

Overall, understanding the key features and capabilities of Fanuc Robots is crucial for harnessing their full potential in industrial automation. By leveraging their precision, versatility, and user-friendly design, you can optimize your manufacturing processes, improve productivity, and stay ahead in the competitive market.

Setting up and programming Fanuc Robots for optimal efficiencySetting up and programming Fanuc Robots for optimal efficiency is a crucial step in maximizing the benefits of automation in manufacturing processes. Fanuc Robots are renowned for their precision, speed, and reliability, but to truly harness their potential, it is essential to set them up correctly.

The first step in setting up a Fanuc Robot is to ensure that it is integrated seamlessly into the existing production line. This involves configuring the robot’s workspace, defining its operating parameters, and establishing communication with other machinery and systems.

Programming the Fanuc Robot is where the magic happens. By creating efficient and optimized motion paths, utilizing advanced features such as vision systems and force sensing, and fine-tuning the robot’s performance through iterative testing and refinement, you can achieve unprecedented levels of productivity and quality in your manufacturing operations.

Moreover, leveraging the intuitive programming interfaces and powerful software tools provided by Fanuc, operators and engineers can quickly develop and modify robot programs to adapt to changing production requirements and optimize performance continuously.

By mastering the setup and programming of Fanuc Robots, manufacturers can unlock a world of possibilities in terms of automation, efficiency, and competitiveness, paving the way for a brighter and more productive future in the realm of manufacturing.

Advanced tips and techniques for improving productivity with Fanuc RoboticsWhen it comes to maximizing productivity with Fanuc Robots, implementing advanced tips and techniques can take your operations to the next level. One effective strategy is to leverage the power of data analytics to optimize robot performance. By analyzing key metrics such as cycle times, downtime, and error rates, you can identify areas for improvement and fine-tune robot programming for optimal efficiency.

Another valuable technique is to implement predictive maintenance practices to minimize downtime and prevent costly breakdowns. By monitoring the health of your Fanuc Robots in real-time and addressing potential issues proactively, you can ensure smooth operation and maximize productivity.

Furthermore, exploring advanced programming features such as vision systems and force sensing can enhance the capabilities of your Fanuc Robots and enable them to handle more complex tasks with precision and speed. By staying updated on the latest technological advancements and continuously refining your processes, you can master efficiency with Fanuc Robots and achieve remarkable results in your operations.

Integrating Fanuc Robots with other automation systems for seamless operationIntegrating Fanuc Robots with other automation systems is a crucial step in maximizing efficiency and productivity in your operations. By seamlessly connecting Fanuc Robots with other automation systems, you can create a well-coordinated workflow that optimizes performance and minimizes downtime.

One key aspect of integration is ensuring compatibility between different systems and technologies. Fanuc Robots are known for their flexibility and compatibility with a wide range of automation systems, making them ideal for integration with various production processes.

Moreover, integrating Fanuc Robots with other automation systems allows for centralized control and monitoring of the entire production line. This enables you to streamline operations, identify bottlenecks, and make real-time adjustments to improve overall efficiency.

By leveraging the capabilities of Fanuc Robots and integrating them with other automation systems, you can achieve a seamless operation that enhances productivity, reduces errors, and ultimately drives business success.

Troubleshooting common issues and maximizing uptime with Fanuc RoboticsTroubleshooting common issues and maximizing uptime with Fanuc Robots is essential for maintaining efficiency in your operations. As with any sophisticated machinery, robots can encounter issues that may disrupt production if not addressed promptly. To minimize downtime and ensure your Fanuc Robots are operating at their best, it is crucial to have a comprehensive troubleshooting plan in place.

One common issue that operators may encounter is programming errors or faults in the robot’s motion. By conducting regular checks and testing the robot’s movements, you can identify and rectify any programming issues before they escalate into larger problems. Additionally, keeping the robot’s software updated and following best practices for programming can help prevent these issues from occurring.

Regular maintenance is also key to maximizing uptime with Fanuc Robots. This includes conducting routine inspections, cleaning, and lubrication to ensure that all components are functioning properly. By adhering to a proactive maintenance schedule, you can address potential issues early on and prevent unexpected breakdowns.

Furthermore, having a trained team of operators who are familiar with troubleshooting procedures can help expedite the resolution of any issues that may arise. Providing ongoing training and support to your staff will not only enhance the efficiency of your operations but also contribute to the long-term success of your robotics program.

By proactively addressing common issues and prioritizing uptime, you can master efficiency with Fanuc Robots and optimize your manufacturing processes for increased productivity and profitability.

Case studies and success stories of companies mastering efficiency with Fanuc RobotsCase studies and success stories provide invaluable insights into how companies have successfully implemented Fanuc robots to master efficiency in their operations. These real-life examples serve as powerful illustrations of the transformative impact that automation can have on various industries.

One notable case study is that of Company X, a leading manufacturer in the automotive sector. By integrating Fanuc robots into their production line, Company X was able to significantly increase their throughput and quality while reducing operational costs. The robots streamlined repetitive tasks, such as welding and material handling, allowing the company to reallocate human resources to more value-added activities. As a result, Company X experienced a substantial boost in productivity and a notable improvement in overall efficiency.

Another compelling success story comes from Company Y, a packaging and distribution company. Facing challenges with labor shortages and rising operational expenses, Company Y turned to Fanuc robots to automate their packaging processes. The robots were able to work seamlessly alongside human employees, enhancing speed and accuracy in packaging operations. This not only improved the company’s efficiency but also enabled them to meet growing customer demands with ease.

These case studies highlight the diverse applications of Fanuc robots across different industries and underscore the positive outcomes that can be achieved through strategic automation. By studying these success stories, companies can gain valuable insights and inspiration for their own efficiency optimization journey with Fanuc robots.

Future trends and innovations in Fanuc Robotics for continued efficiency gainsAs technology continues to advance at a rapid pace, the field of Fanuc Robotics is also evolving to meet the demands of the future. In this section, we will explore some of the key trends and innovations in Fanuc Robotics that are poised to drive continued efficiency gains for businesses.

One of the most exciting trends in Fanuc Robotics is the integration of artificial intelligence and machine learning capabilities. By incorporating AI algorithms into robotic systems, Fanuc Robots can now learn from experience, adapt to changing environments, and optimize their performance over time. This not only enhances the efficiency of robotic operations but also enables robots to work alongside human operators in a seamless and collaborative manner.

Another important innovation in Fanuc Robotics is the development of collaborative robots, also known as cobots. These robots are designed to work safely alongside human workers, opening up new possibilities for automation in industries where close human-robot interaction is required. By leveraging cobots, businesses can achieve greater flexibility, productivity, and efficiency in their operations.

Furthermore, advancements in sensor technology, connectivity, and data analytics are enabling Fanuc Robots to gather and analyze vast amounts of data in real-time. This data-driven approach allows businesses to monitor and optimize their robotic systems for maximum efficiency, predictive maintenance, and continuous improvement.

In conclusion, the future of Fanuc Robotics is bright, with exciting trends and innovations on the horizon that promise to revolutionize the way businesses leverage robotic technology for efficiency gains. By staying informed and embracing these advancements, businesses can position themselves for success in an increasingly automated and competitive marketplace.

Training and resources available for mastering efficiency with Fanuc RobotsWhen it comes to mastering efficiency with Fanuc Robots, having access to the right training and resources is crucial. Fanuc offers a comprehensive range of training programs and resources to help users maximize the potential of their robots.

One of the key training options available is the Fanuc CERT program, which provides hands-on training in programming, operation, maintenance, and troubleshooting of Fanuc robots. This program is designed to equip users with the skills and knowledge needed to optimize the performance of their robots and improve overall efficiency.

In addition to training programs, Fanuc also provides a wealth of online resources, including user manuals, technical documentation, video tutorials, and troubleshooting guides. These resources are invaluable for users looking to expand their knowledge and troubleshoot any issues that may arise during operation.

By taking advantage of the training programs and resources offered by Fanuc, users can enhance their proficiency with Fanuc robots, increase productivity, and ultimately achieve higher levels of efficiency in their operations.

Conclusion: Embracing the power of Fanuc Robots for enhanced productivity and efficiencyIn conclusion, the integration of Fanuc Robots into your industrial processes can truly revolutionize the way your business operates. These advanced robotic systems offer a myriad of benefits, including increased productivity, enhanced efficiency, improved accuracy, and reduced downtime.

By harnessing the power of Fanuc Robots, you can streamline your production lines, automate repetitive tasks, and optimize your workflow for maximum output. The precision and reliability of Fanuc Robots ensure consistent quality and performance, leading to higher customer satisfaction and increased profitability.

Embracing the technology of Fanuc Robots is not just about staying competitive in the market; it is about setting new standards for excellence and innovation in your industry. With their cutting-edge features and versatility, Fanuc Robots empower businesses to achieve new levels of efficiency and success.

So, take the leap and explore the possibilities that Fanuc Robots offer. By mastering efficiency with these advanced robotic systems, you can propel your business towards a future of unparalleled productivity and growth.

We hope this comprehensive guide on mastering efficiency with Fanuc Robots has been informative and helpful to you. Fanuc robots are cutting-edge tools that can revolutionize the way you approach automation and manufacturing processes. By following the tips and strategies outlined in this blog post, you can harness the full potential of Fanuc robots and optimize your operations for maximum efficiency and productivity. Embrace the power of automation and watch your business soar to new heights!